Trim Cutters

Trim Cutter

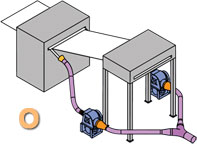

If your converting line creates edge trim, the by-product is an opportunity to save time and money. Increase production up-time and allow your converting machinery to run at full speed with a BloApCo Trim Cutter as part of your comprehensive scrap handling system.

Trim Cutters enable continuous web manufacturers, slitters and converters to remove edge trim from production lines while maximizing up-time by eliminating edge trim blockages. They cut continuous material into small pieces that move with ease to a collection area such as a baler or compactor, and are ideal wherever one or more edge trims are conveyed through the same duct.

Models

Related Literature

![]() Bulletin 991: Trim Cutters

Bulletin 991: Trim Cutters

![]() Bulletin 991: Supplement: Trim Cutters

Bulletin 991: Supplement: Trim Cutters

![]() Application Report 10: Continuous Laminated Edge Trims

Application Report 10: Continuous Laminated Edge Trims

![]() Application Report 22: Continuous Web of Paper Waste

Application Report 22: Continuous Web of Paper Waste

![]() Application Report 23: Disposal of Stiff Scrap Matrix

Application Report 23: Disposal of Stiff Scrap Matrix

BEST USES Removal of continuous film, Edge Trim and Matrix

Removal of continuous film, Edge Trim and Matrix

INDUSTRIES Converting, Paper, Film, Plastic, Non-woven, Foils

Converting, Paper, Film, Plastic, Non-woven, Foils

MATERIALS From 0.00025 inches (6.35 ¼m) to 0.25 inches (6350 ¼m)

From 0.00025 inches (6.35 ¼m) to 0.25 inches (6350 ¼m)

- light paper

- poly films

- recording tape

- Mylar

- fine nylon fibers

- non-wovens

- paper

- light fiberboard

- corrugated board

- solid bleached sulfate, paperboard

- plastic film

- foil laminates

- pressure-sensitive stock

- light, non-ferrous foils

- heavy fiberboard

- solid bleached sulfate paperboard

- laminated kraft, heavy non-ferrous metal up to 0.025 in.

Motor Positions

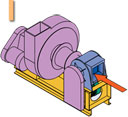

Standard Cutter Arrangement

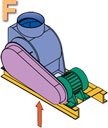

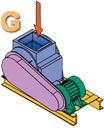

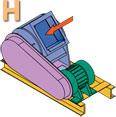

Inverted Mount

Outboard Motor Mount

Direct Drive Motor Mount

Cutter Head Positions*

Diagonal Flow, Standard Mount

Vertical Up Flow

Vertical Down Flow

Diagonal Flow, Inboard Motor Mount

Cutter Mounting Arrangements

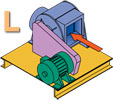

Rail Mounted Cutter and Trim Fan

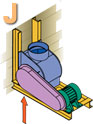

Wall Mounted Cutter

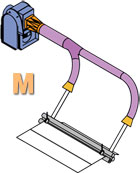

Ceiling Suspended Cutter

Low Clearance Cutter Mount

Trim Removal

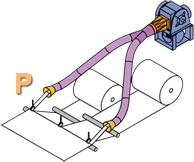

Dual pickups from top to offset trim cutter

Dual pickups from bottom to offset trim cutter

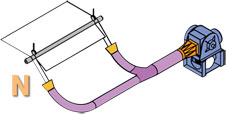

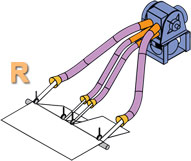

Dual pickups to tandem trim cutters ideally suited for corrugator edge trim

Dual pickups to inline trim cutter

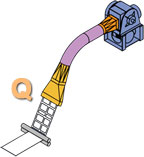

Narrow web matrix from top to trim cutter

Multiple pickups to single trim cutter

Trim Cutter Specs

Light

less than 1 mil (25.4µm)

Ideal for:

- Light paper

- Poly films

- Recording tape

- Mylar

- Fine nylon fibers

- Non-wovens

Some models will accurately and consistently cut film as thin as 0.000025 in. (6.35 µm) with ease.

Model 7-6

Air Capacity 1,000 cfm (1,700 m3/hr)

Inlet Width 7.75 in. (206 mm)

Motor 1hp rpm 3,600 max

Model 7-7

Air Capacity 1,000 cfm (1,700 m3/hr)

Inlet Width 7 in. (176 mm)

Motor 1hp rpm 2,000 max

Model 8-5

Air Capacity 4,500 cfm (7,650 m3/hr)

Inlet Width 13.5 in. (343 mm)

Motor 5hp rpm 3,600 max

Medium

3-20 mil (76 – 508µm)

Ideal for:

- paper

- light fiber board

- corrugated board

- solid bleached sulfate paperboard

- plastic film

- foil laminates

- pressure-sensitive stock

- light, non-ferrous foils

Model 3B

Air Capacity 1,000 cfm (1,700 m3/hr)

Inlet Width 6.25 in. (159 mm)

Motor .75 hp rpm 2,000 max

Model 5TOB / 5SC

Air Capacity 3,000 cfm (5,100 m3/hr)

Inlet Width 8.5 in. (216 mm)

Motor 2 hp rpm 2,000 max

Model 7-6

Air Capacity 1,000 cfm (1,700 m3/hr)

Inlet Width 7.75 in. (206 mm)

Motor 1 hp rpm 3,600 max

Model 7-7

Air Capacity 1,000 cfm (1,700 m3/hr)

Inlet Width 7 in. (176 mm)

Motor 1 hp rpm 2,000 max

Model 8-3

Air Capacity 4,500 cfm (7,650 m3/hr)

Inlet Width 13.5 in. (343 mm)

Motor 5 hp rpm 2,000 max

Model 8-5

Air Capacity 4,500 cfm (7,650 m3/hr)

Inlet Width 13.5 in. (343 mm)

Motor 5 hp rpm 3,600 max

Heavy

20 mil (508µm and up)

Ideal for:

- heavy fiberboard

- solid bleached sulfate paperboard

- laminated kraft, heavy non-ferrous metal up to 0.025 in.

Model 5TOB / 5SC

Air Capacity 3,000 cfm (5,100 m3/hr)

Inlet Width 8.5 in. (216 mm)

Motor 2 hp rpm 2,000 max

Model 8-3

Air Capacity 4,500 cfm (7,650 m3/hr)

Inlet Width 13.5 in. (343 mm)

Motor 5 hp rpm 2,000 max

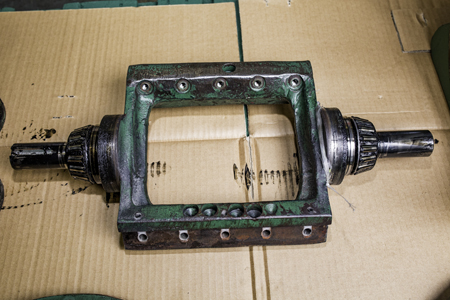

Keep your Trim Cutter Running at Peak Condition

- Total Trim Cutter Refurbishment

- Replacement Knives

- Knife Sharpening

Total Trim Cutter Replacement

Your BloApCo Trim Cutter is built to last! Like any manufacturing equipment, a regular schedule of maintenance is required. BloApCo’s comprehensive refurbishment service will have your Trim Cutter back to peak condition.

Upon thorough inspection BloApCo will provide a cost estimate and a summary of the specific steps necessary to completely refurbish your Trim Cutter.

An overview of the Refurbishment Process:

Trim Cutter Arrives at BloApCo

Complete Teardown and Inspection

Cutter Components Thoroughly Cleaned and Prepped for Reassembly

Reassembly. New and Reconditioned Components set to Original Factory Settings

Painting, Finishing and Secured for Shipping

Back to you as good as new!

BloApCo will ship your refurbished Trim Cutter to you within two to three weeks of an accepted proposal.

Call BloApCo at 800-959-0880 or complete the form below for a cost estimate. For faster service have your Trim Cutter Model and Serial numbers handy a quotation.